FOR OVER 50 YEARS, A RELIABLE PARTNER

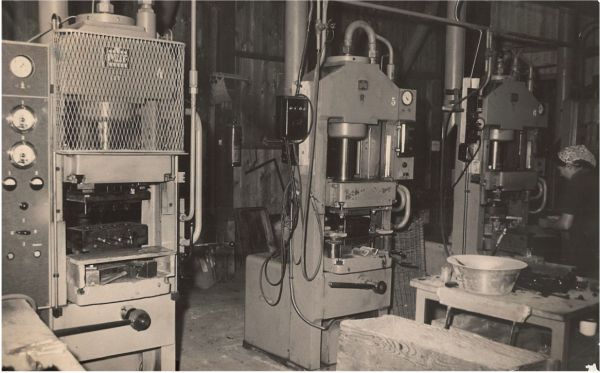

1954

Establishment of Karl-Hans-Bauer Kunststoffverarbeitung in Sulzbach-Laufen, Swabia, and of VEB Schaltelektronik Oppach in Königstein, Saxony

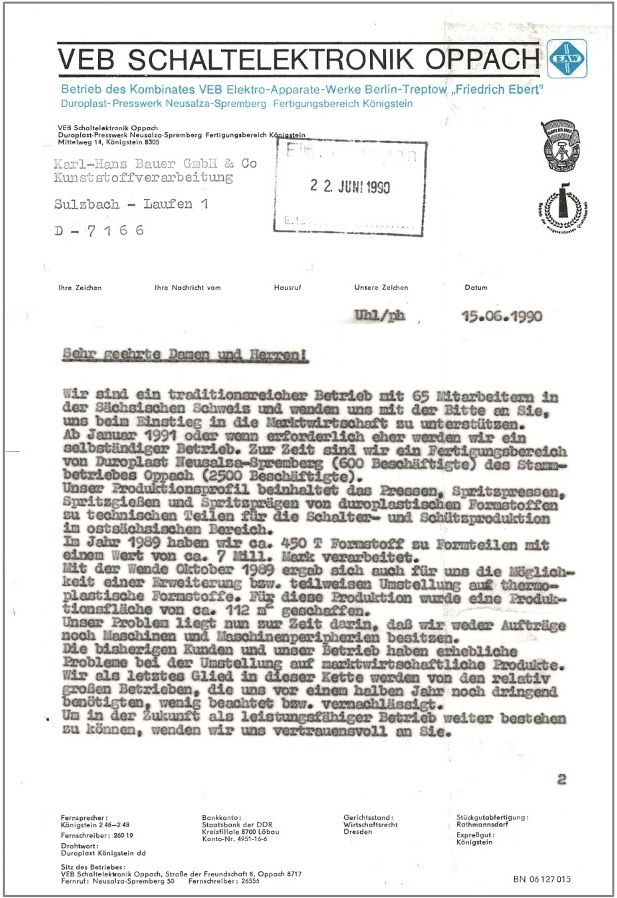

1990

Start of collaboration.

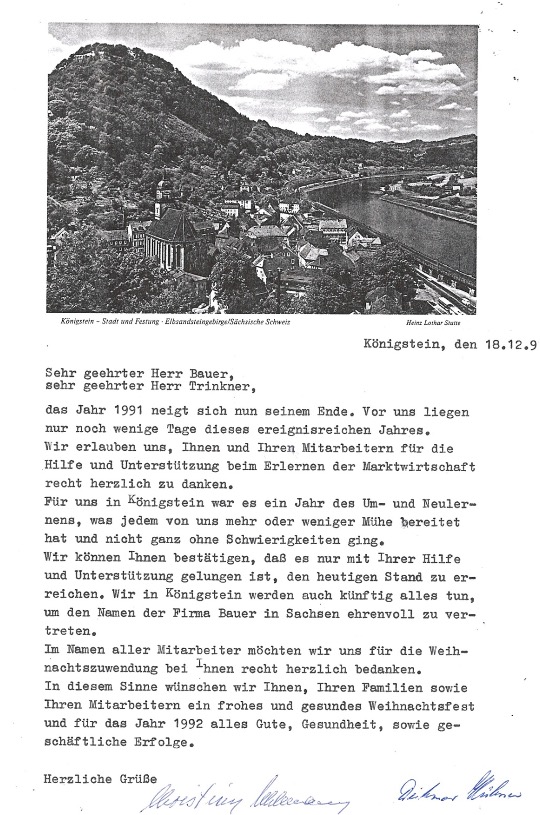

1991

Acquisition of the company and official founding of Kunststoffverarbeitung Bauer GmbH

1995

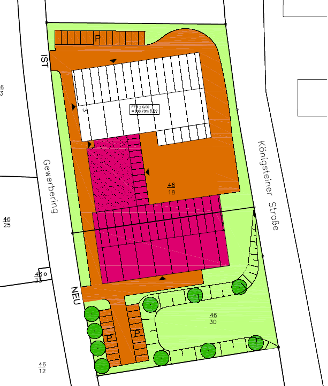

Construction begins at a new location in the Leupoldishein industrial park

1996

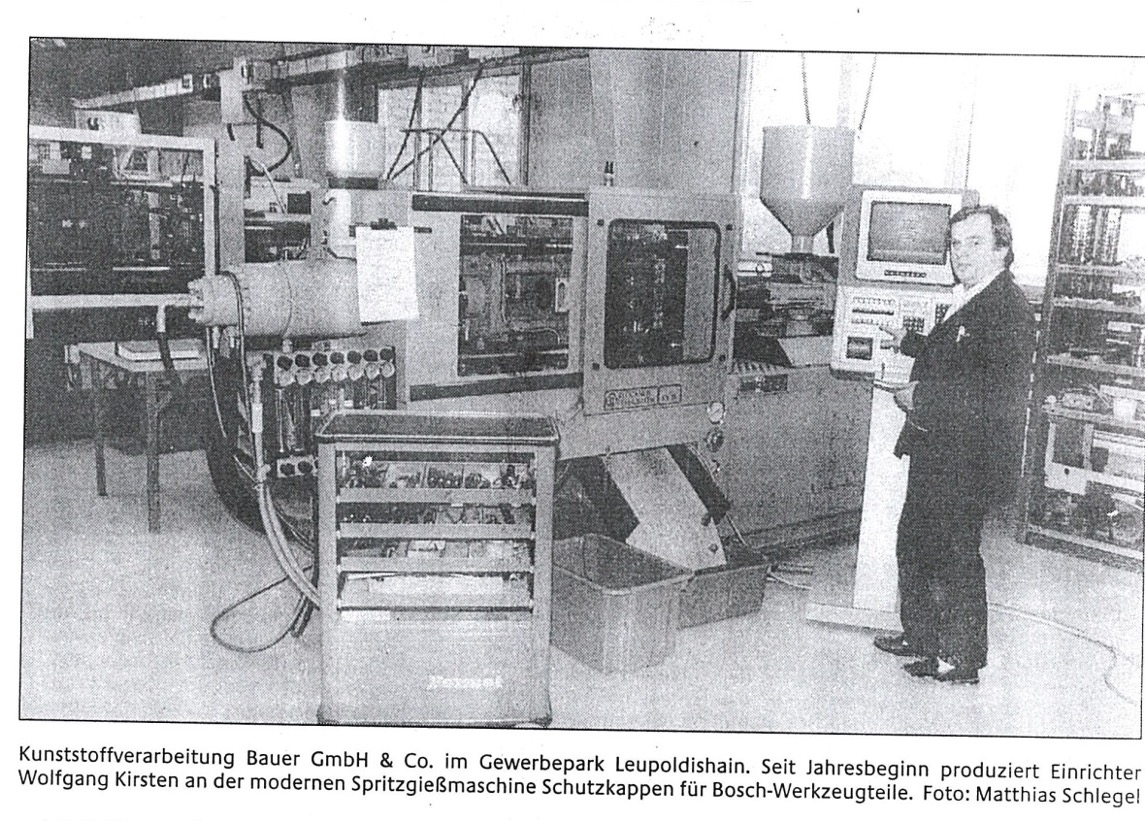

Relocation to the new building

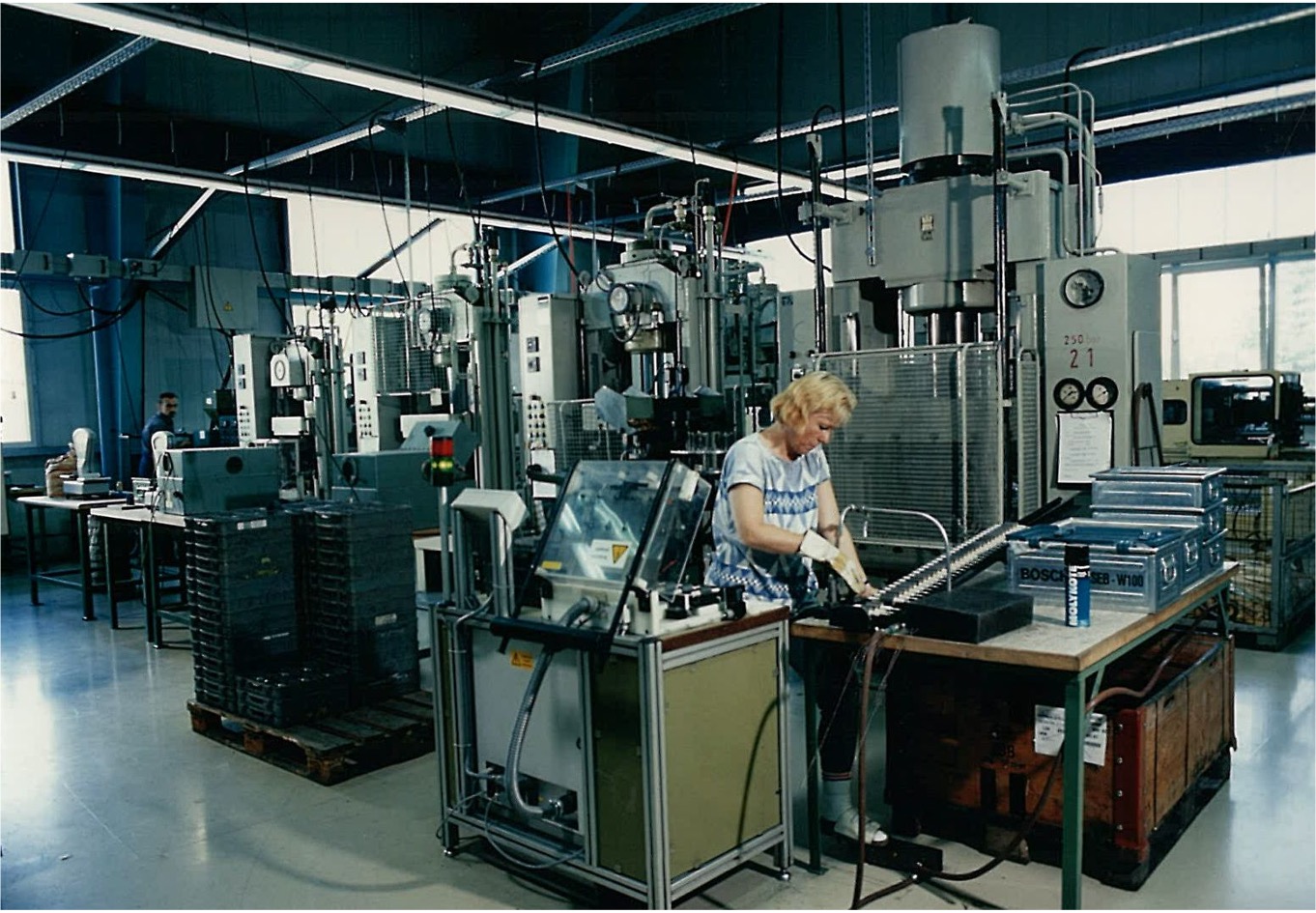

1996

Start of the partnership with Bosch Power Tools

1997

Initial certification in compliance with DIN ISO 9001

2002

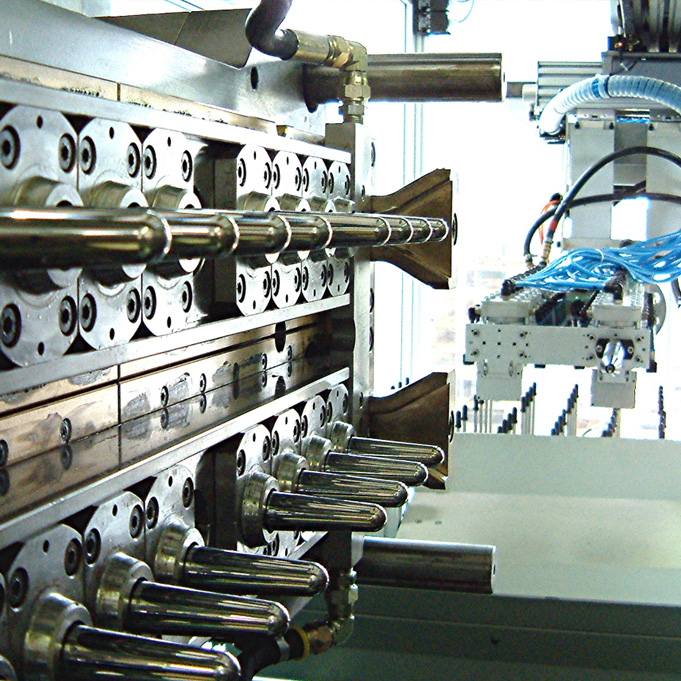

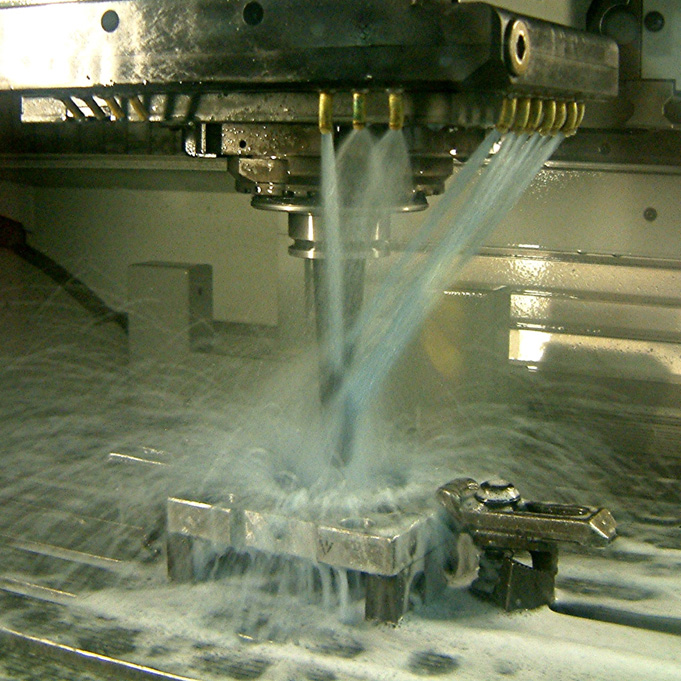

Separation from the sister company, expansion of the toolmaking department, and start of preform production

2011

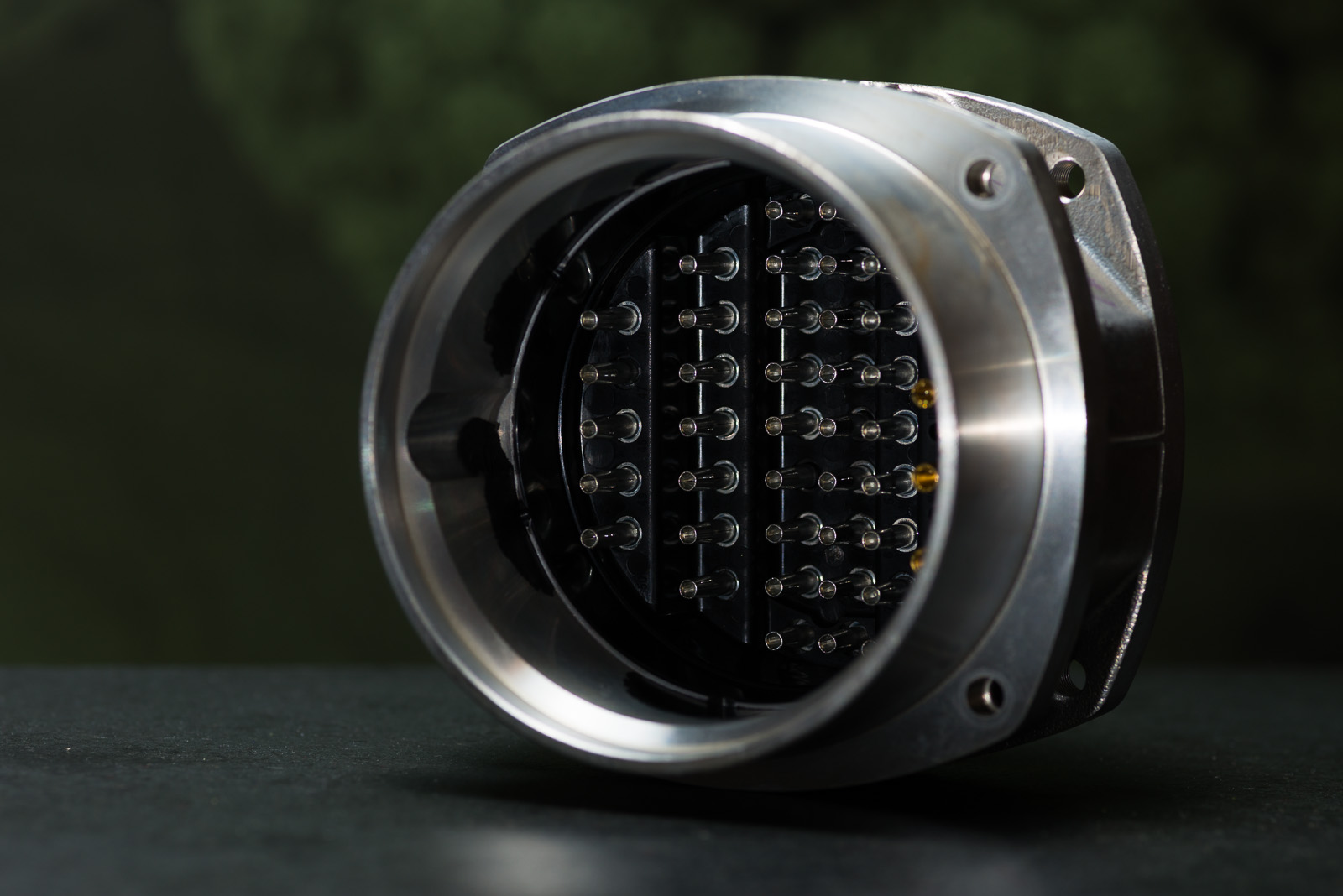

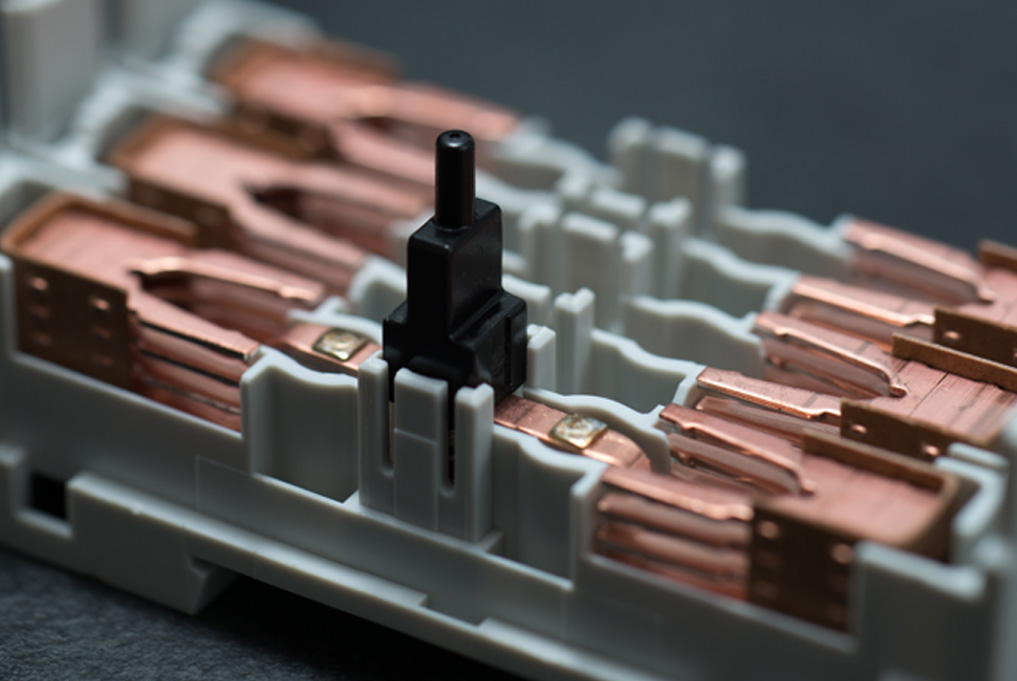

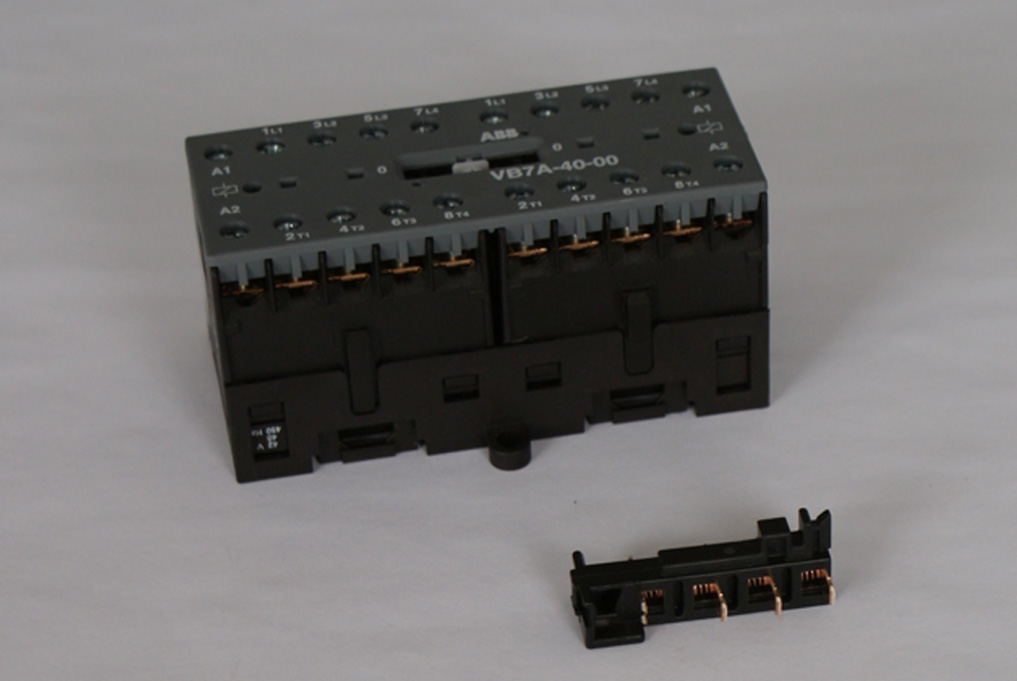

Addition of 1900m² of manufacturing space and 400m² of office space, start of production of clamp connectors

2012

Topping-out ceremony, relocation, inaugural celebration.

2013

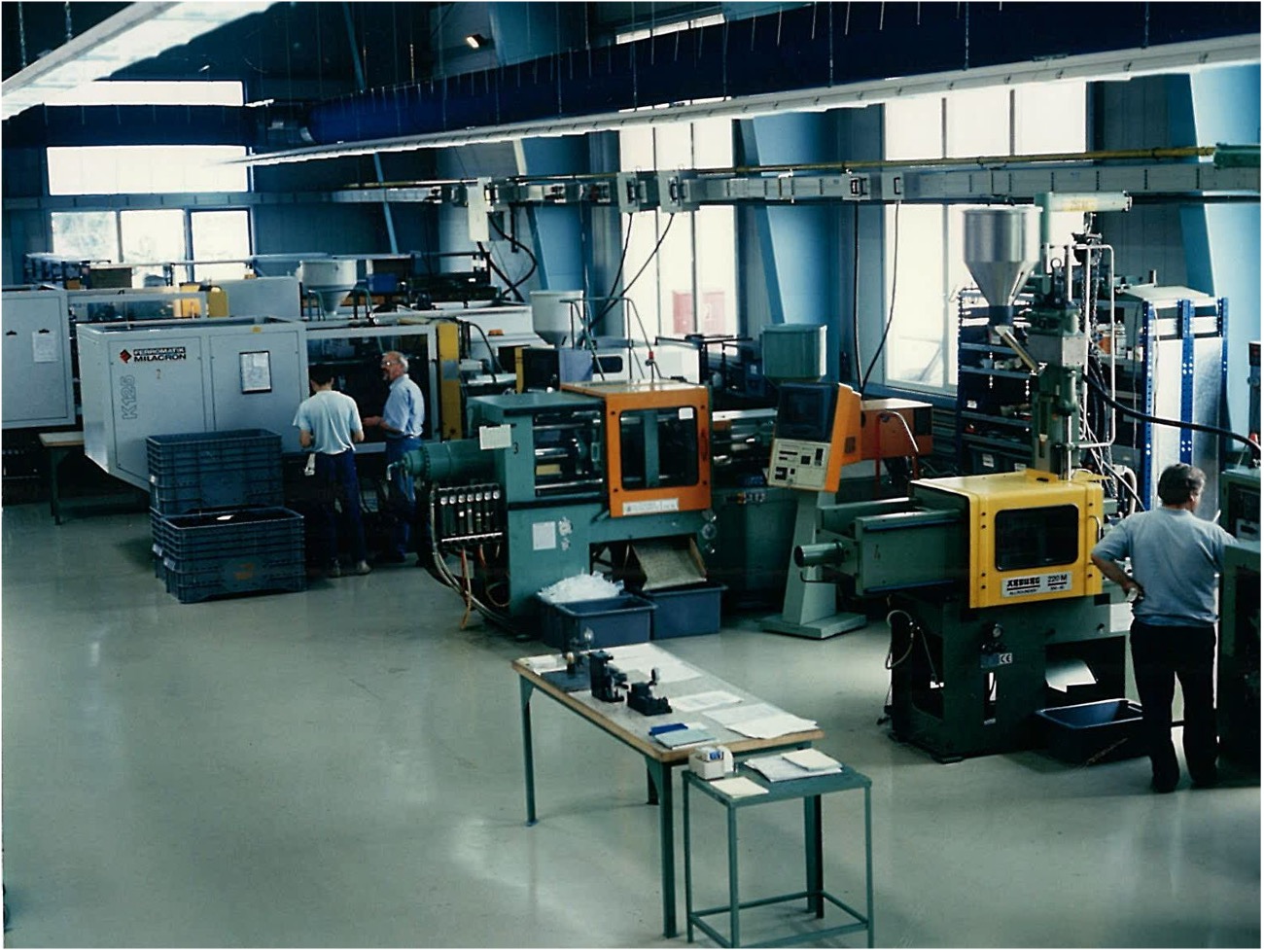

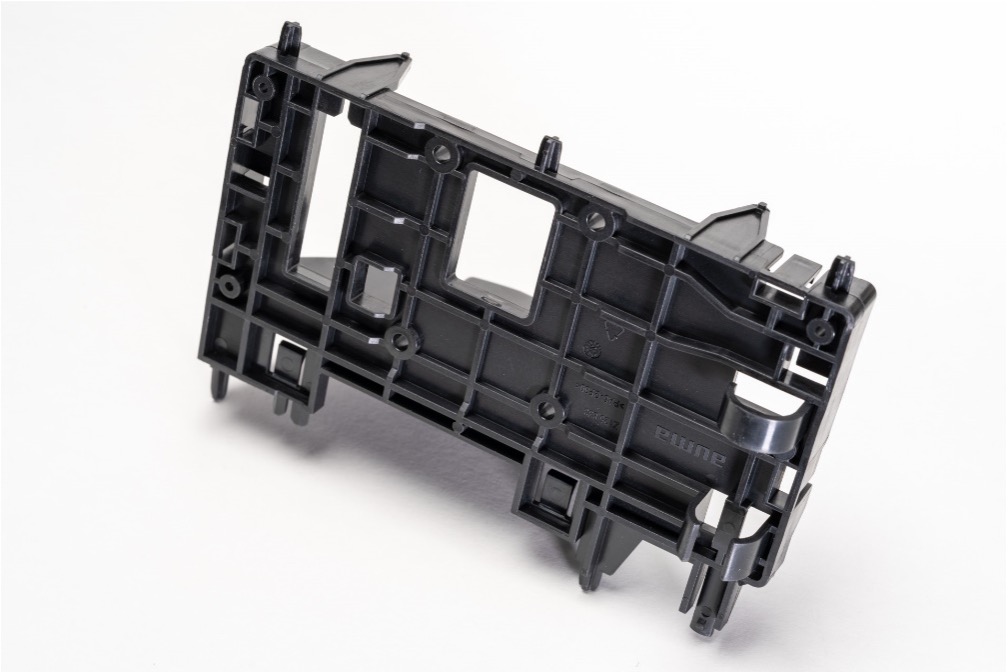

Series production begins of new ABB pieces, acquisition of additional injection molding machines.

2014

New corporate design and first appearances at trade fairs

2015

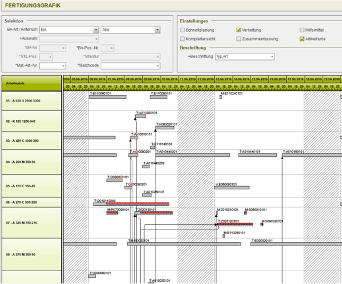

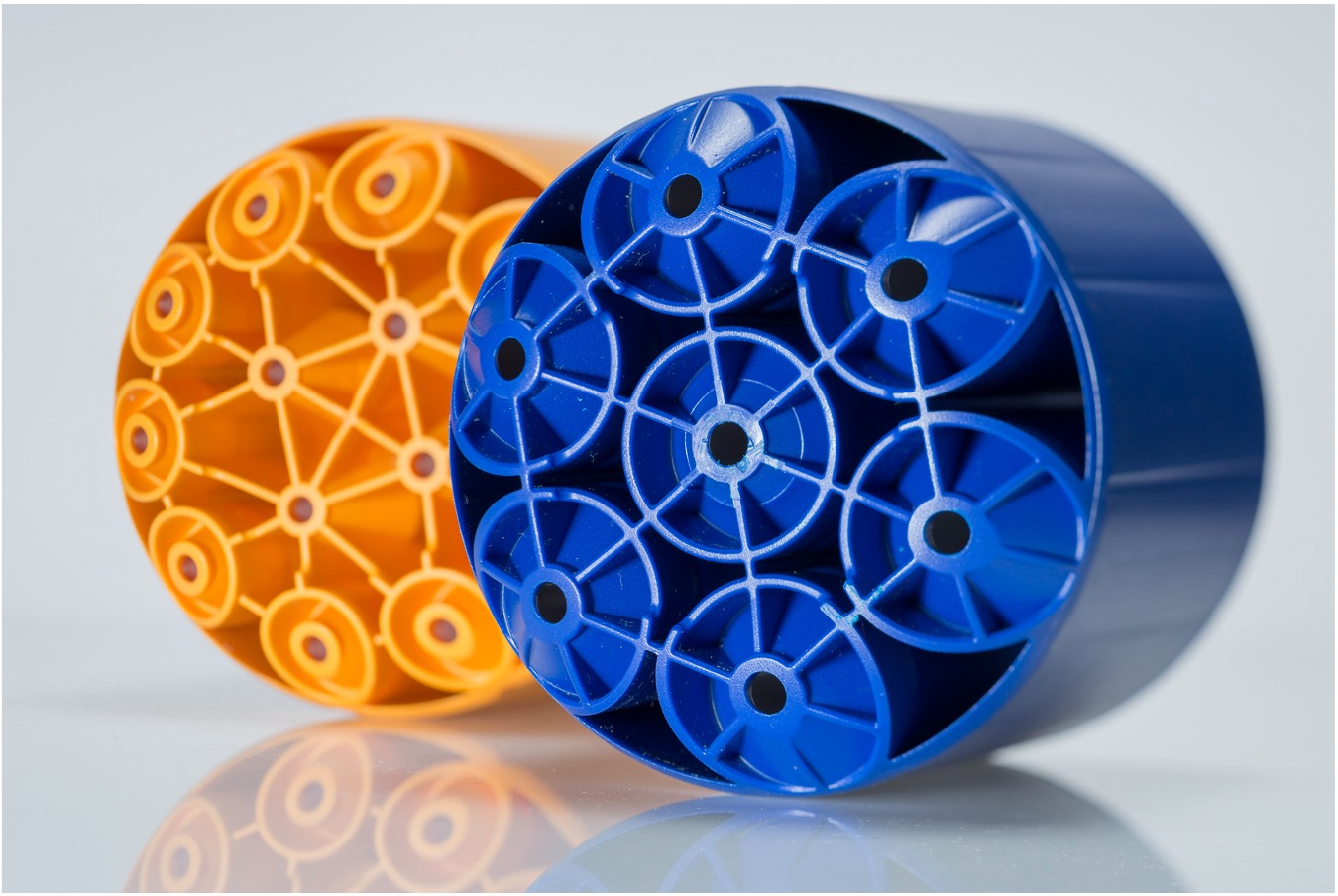

Implementation of the Wincarat ERP system and start of collaboration with Eppendorf

2015

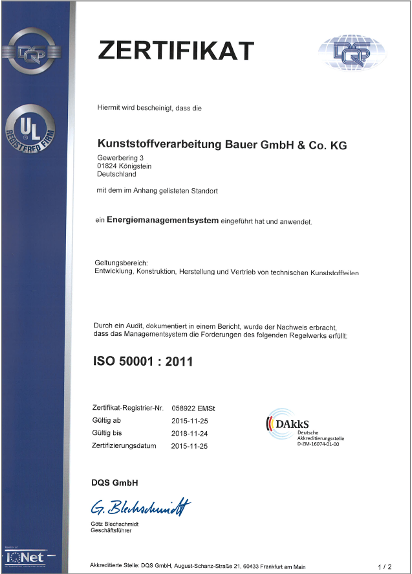

Initial certification under DIN ISO 50001 and transfer of executive leadership responsibilities to Bettina Trinkner

2016

Sale of our partner company PET Sachsen GmbH & Co. KG

2018

Start of series production of arc extinguishing tubes for switchgear for our customer UESA and acquisition of additional thermoplastic injection molding machines ranging from 50t to 150t clamping force; implementation begins of the ALS operational data capture system

2019

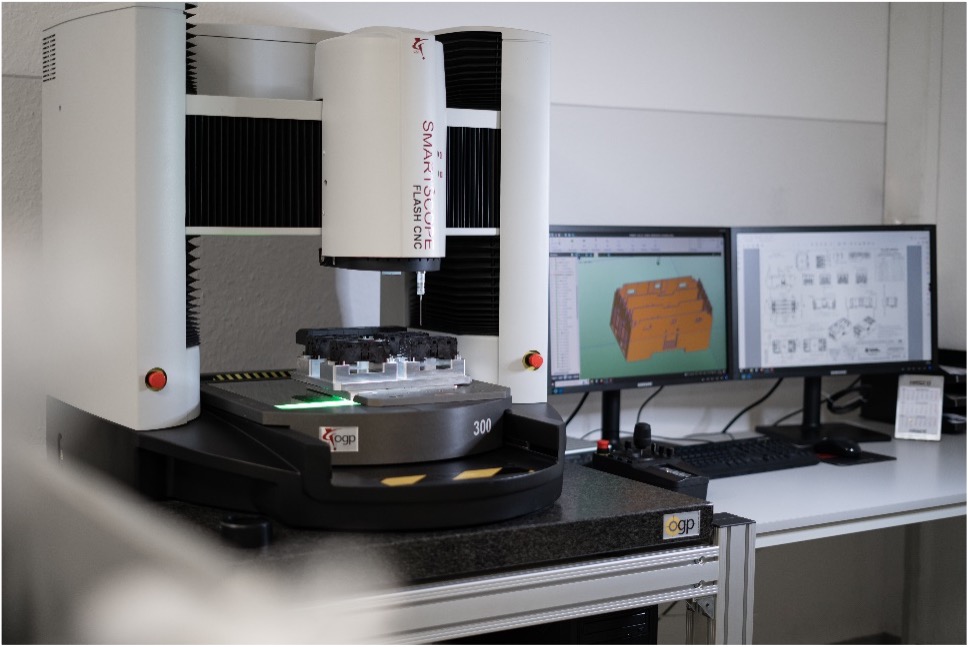

Expansion of the collaboration with Siemens Healthineers through acquisition of several epoxy resin tools. Investment in a 3D measuring machine (optical-tactile) and an injection molding machine with special equipment for extremely small shot weights.

2020

Start of series production for some very complex articles with part weights under 1g for our new customer Rockwell Automation, and replacement purchase of a grinding machine for our toolmaking department.

2022

Purchase of additional Arburg injection molding machines, including our first fully electric, automated system. Expansion of the toolmaking department